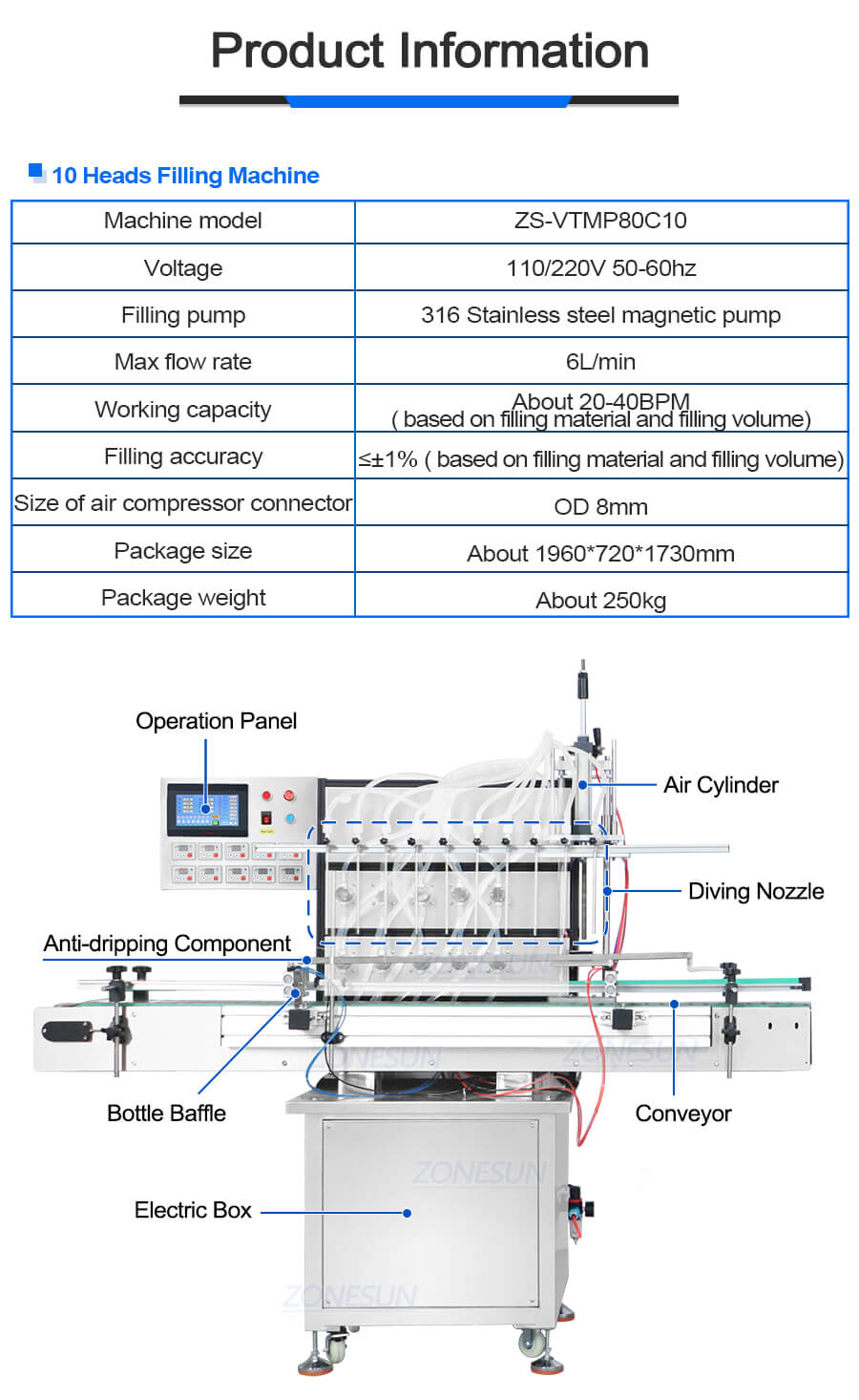

This liquid filling line is consist of 10 heads filling machine, stopper pressing and cap screwing machine, it can finsh liquid filling, stopper pressing, cap screwing at the same time. It can also connect with automatic labeling machine and bottle turntable machine to save working labor.

The PLC control panel can shows working data in real time, more intuitive interface can simplifies machine operation. It can be customized into different kinds of language according to production need.

Filling work is controlled by 316 stainless steel magnetic pump, it has higher filling accuracy.Diving filling nozzle can prevent liquid from spraying out during filling work, it is good for foamy liquid. Multiple filling nozzles can be customized as needed.

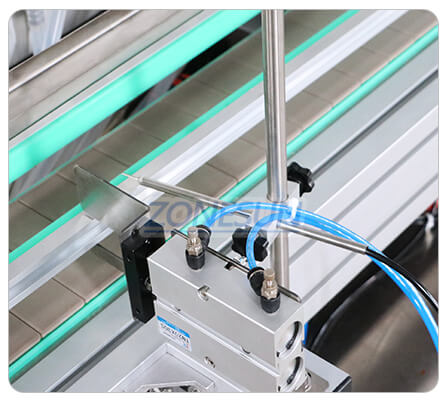

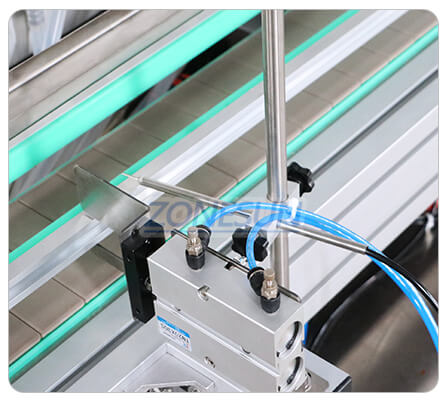

Electric eye can detect passing by bottles and send signals to the system to control machine to start filling and capping work automatically. It improves working efficiency.

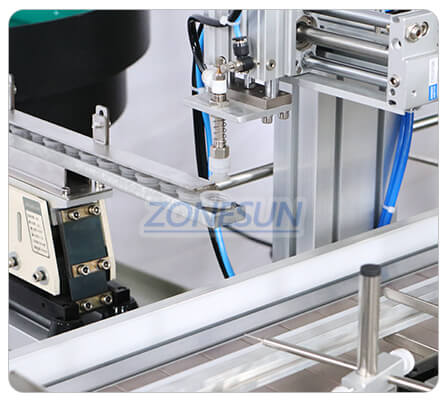

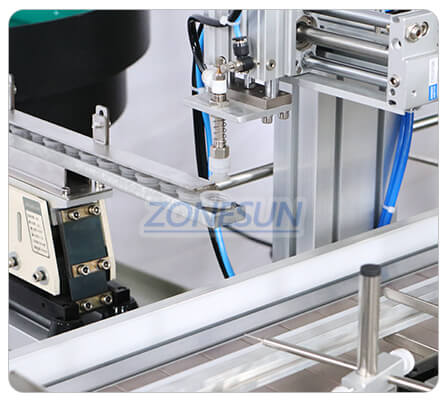

Controlled by air cylinder, the air nozzles can pass stoppers and put them onto bottle mouth like human hand, this suits the light caps or stoppers, it has high working accuracy.

By automating the sorting process, vibratory bowl sorting machines reduce the need for manual labor, resulting in increased efficiency and productivity. They are customized according to stoppers and caps size, and have high working accuracy.

Working height and position of capping structure can be adjusted according to bottle cap size and shape.This kind of capping structure is suitable for various kinds of caps like spark caps, dropper bottles, sharp pointed bottles.

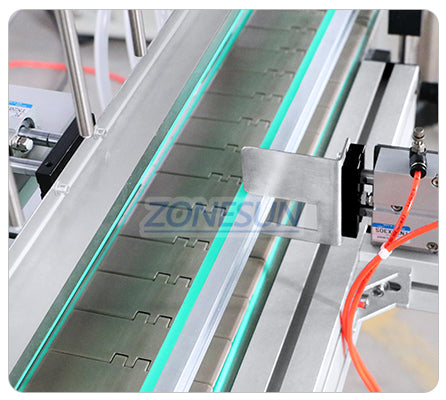

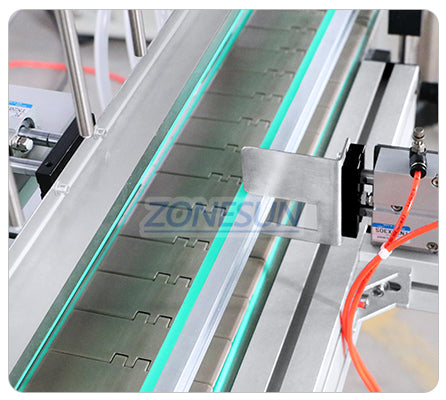

Length and width of chain conveyor can be customized according to production needs. It has larger weight capacity and can convey products more stably and smoothly.