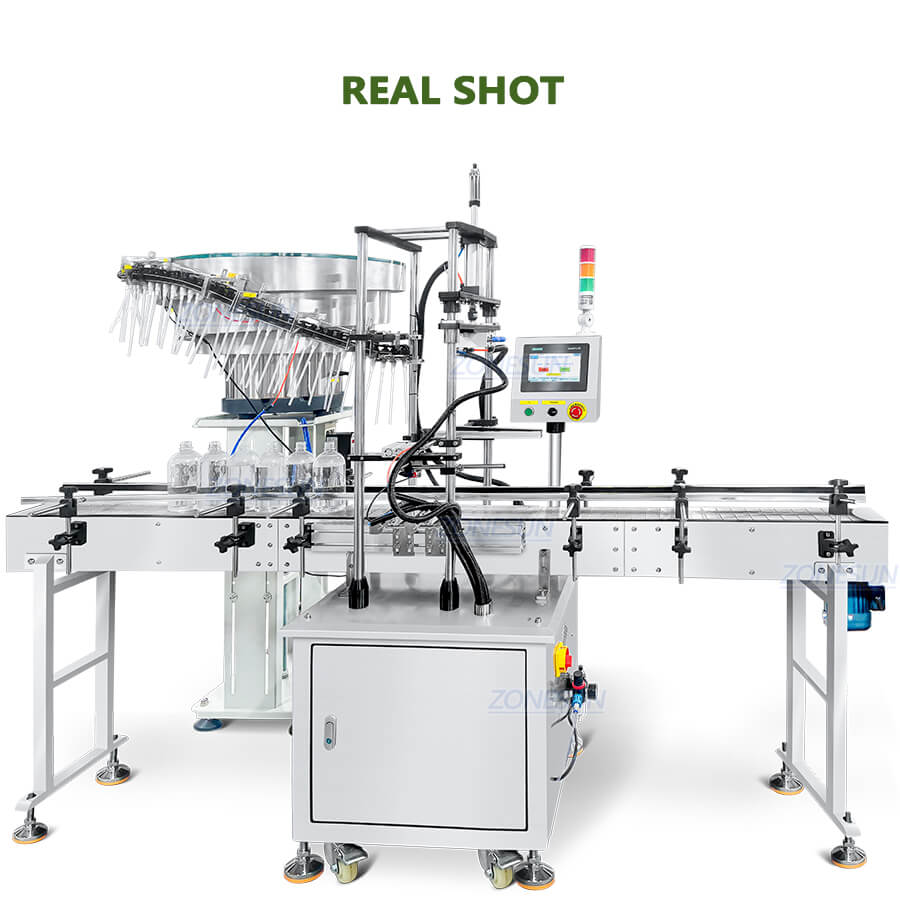

The spray tubes of some trigger pump spray caps are long and hard, so during the process of inserting the cap, you may be faced with the difficulty of accurately placing the cap into the bottle, making it impossible to achieve automated work. This cap feeding machine can imitate human hands to take caps and accurately place caps into bottles. The working speed can reach 23 bottles/minute. This machine can be connected with filling machines, capping machines, and labeling machines to achieve complete packaging production work.

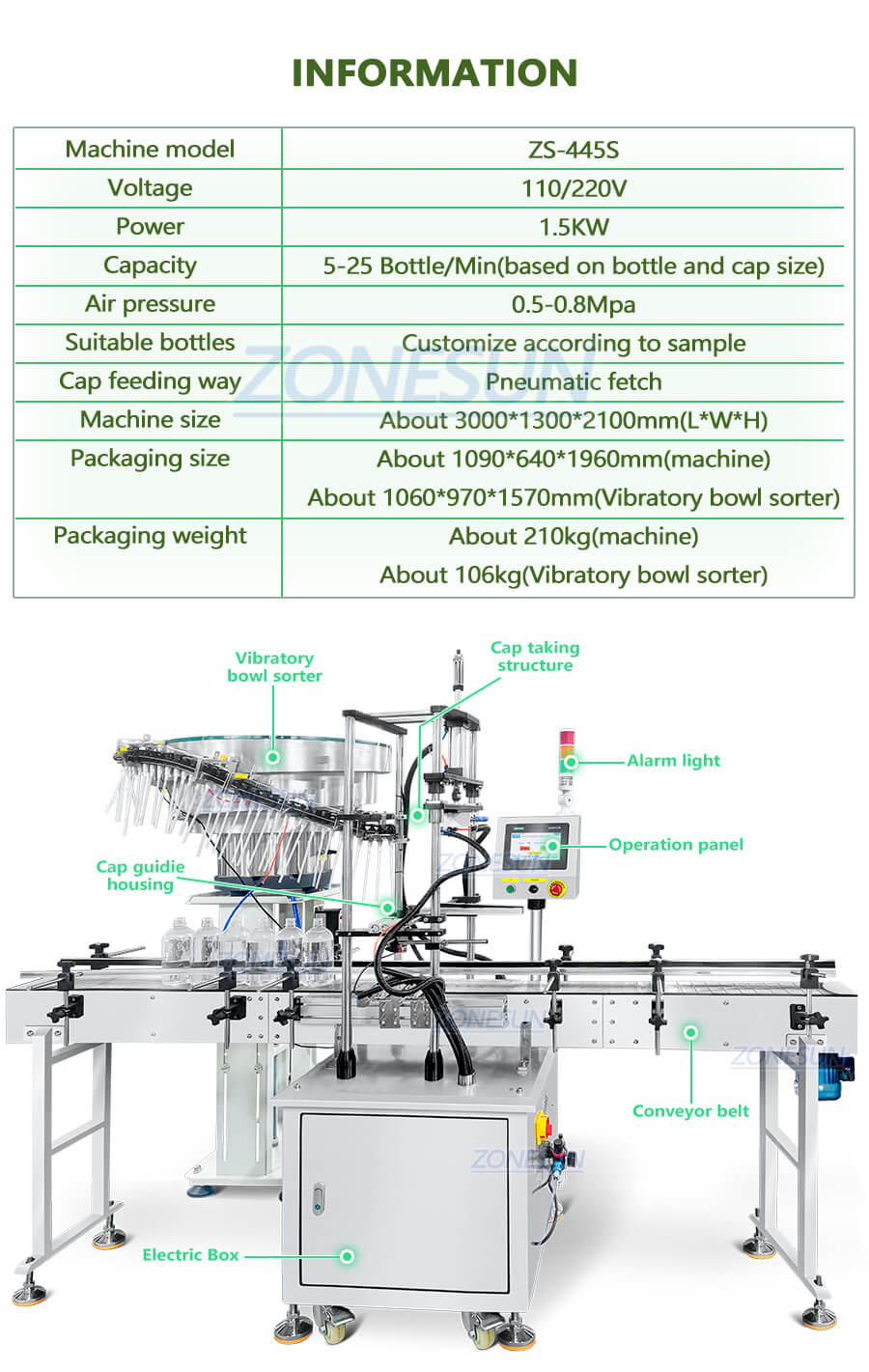

Parameter

-

Machine model:ZS-445S

-

Voltage:110/220V

-

Power:1.5KW

-

Capacity:5-25 Bottle/Min(based on bottle and cap size)

-

Air pressure:0.5-0.8Mpa

-

Suitable bottles:Customize according to sample

-

Cap feeding way:Pneumatic fetch

-

Machine size:About 3000*1300*2100mm(L*W*H)

-

Packaging size:About 1090*640*1960mm(machine)+About 1060*970*1570mm(Vibratory bowl sorter)

-

Packaging weight:About 210kg(machine)+About 106kg(Vibratory bowl sorter)

Equipped with touch screen control panel,this makes it visual to debug the machine.Different kinds of operation language can be customized as operation need. Alarm lights can be configured to indicate various states or conditions of the machine, this ensures timely responses to critical events.

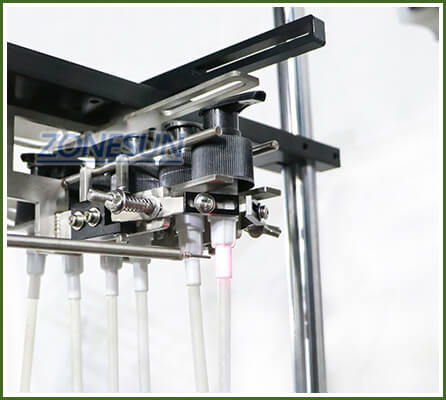

This machine can imitate human hands to take caps and accurately place caps into bottles, this machine is suitable for trigger pump sprayer with long and hard tubes.

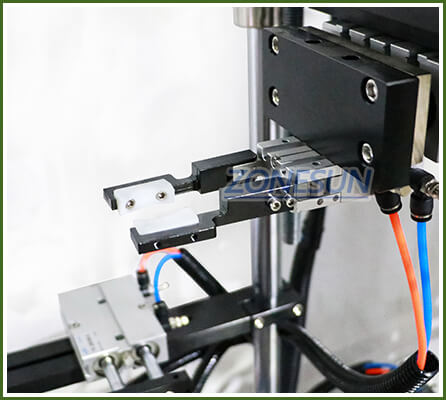

The cylinder controls the work of the components to ensure the smooth progress of the cap taking. The working height of this component can be adjusted as needed to ensure it is suitable for different sizes of trigger pump caps.

There is a sensor , which is used to detect spray caps , if there is no enough caps, it will send signal to the system and control the machine to supply caps in time, improves working efficiency.

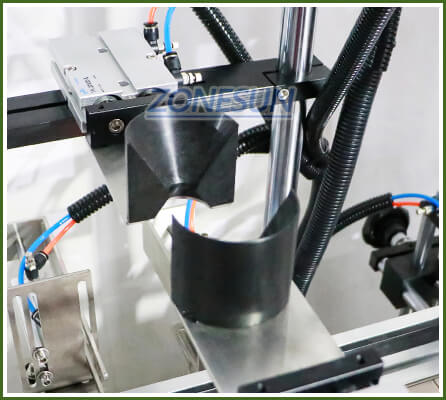

By ensuring smooth and precise movement of machine elements, guide housings contribute to improved performance and productivity.

Equipped with chain conveyor belt,this has large weight capacity to transport bottles.The width of conveyor belt can be customized according to operation need.